SOLAR COLLECTORS

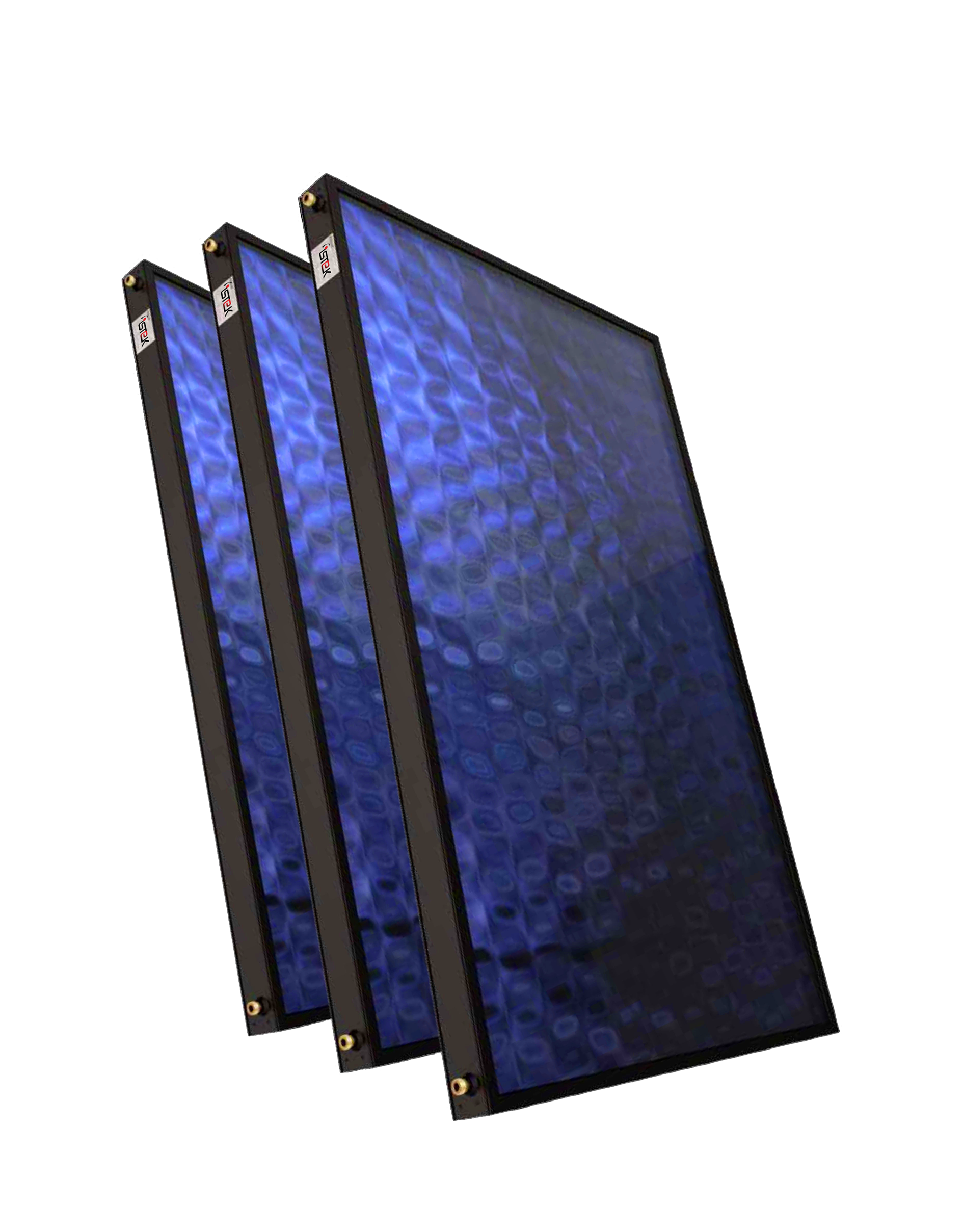

Istek Cu+

Excellence in Solar Energy

Istek Cu+ is a high-performance selective surface copper tube solar collector designed with advanced technology. It was developed to provide maximum efficiency from solar energy and offer a long-lasting solution.

Why Istek Cu+?

High Energy Efficiency: Thanks to its selective surface, it absorbs sunlight in the most efficient way and converts it into energy.

Durability: High-level materials and engineering provide a long-lasting and weather-resistant structure.

Economic and Environmentally Friendly: Provides an environmentally friendly solution while reducing energy costs.

Advanced Technology: Provides reliable performance with modern production techniques and innovative design.

BOILER

VERTICAL BOILER

Vertical coil boilers, with their vertical design, provide space-saving solutions while optimizing the natural circulation of hot water and ensuring homogeneous heat distribution. These boilers, equipped with a specially designed coil system, transfer energy quickly and efficiently, offering compatibility with different energy sources through single or double coil options. They work in perfect harmony with solar collectors, eliminating the necessity of being placed above the collectors, thus providing flexible installation options. Standing out with high-pressure resistance, long-lasting structure, and user-friendly design, vertical coil boilers are an ideal choice for energy savings and sustainable use. They offer efficient, reliable, and modern hot water solutions for both residential and commercial spaces.

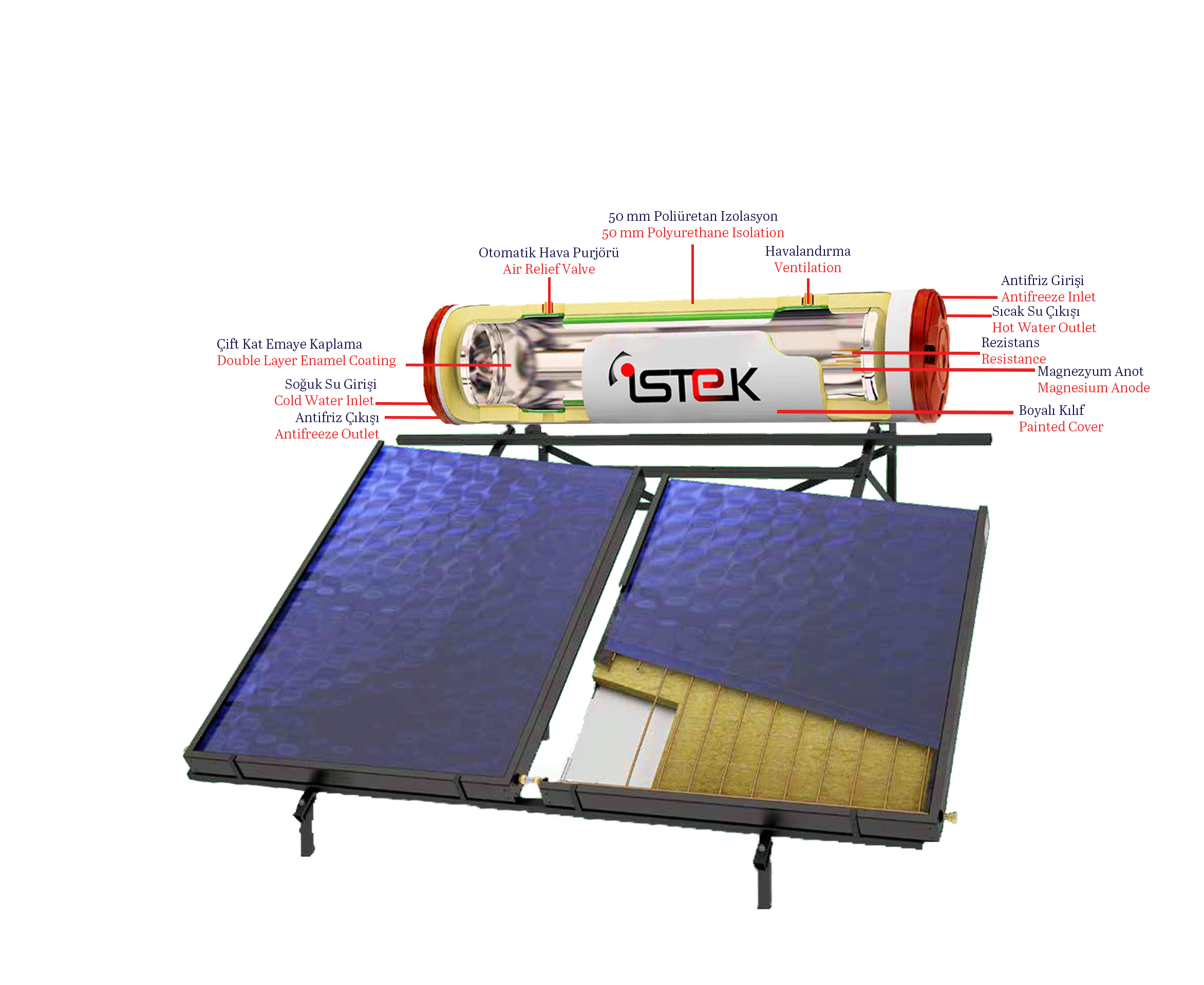

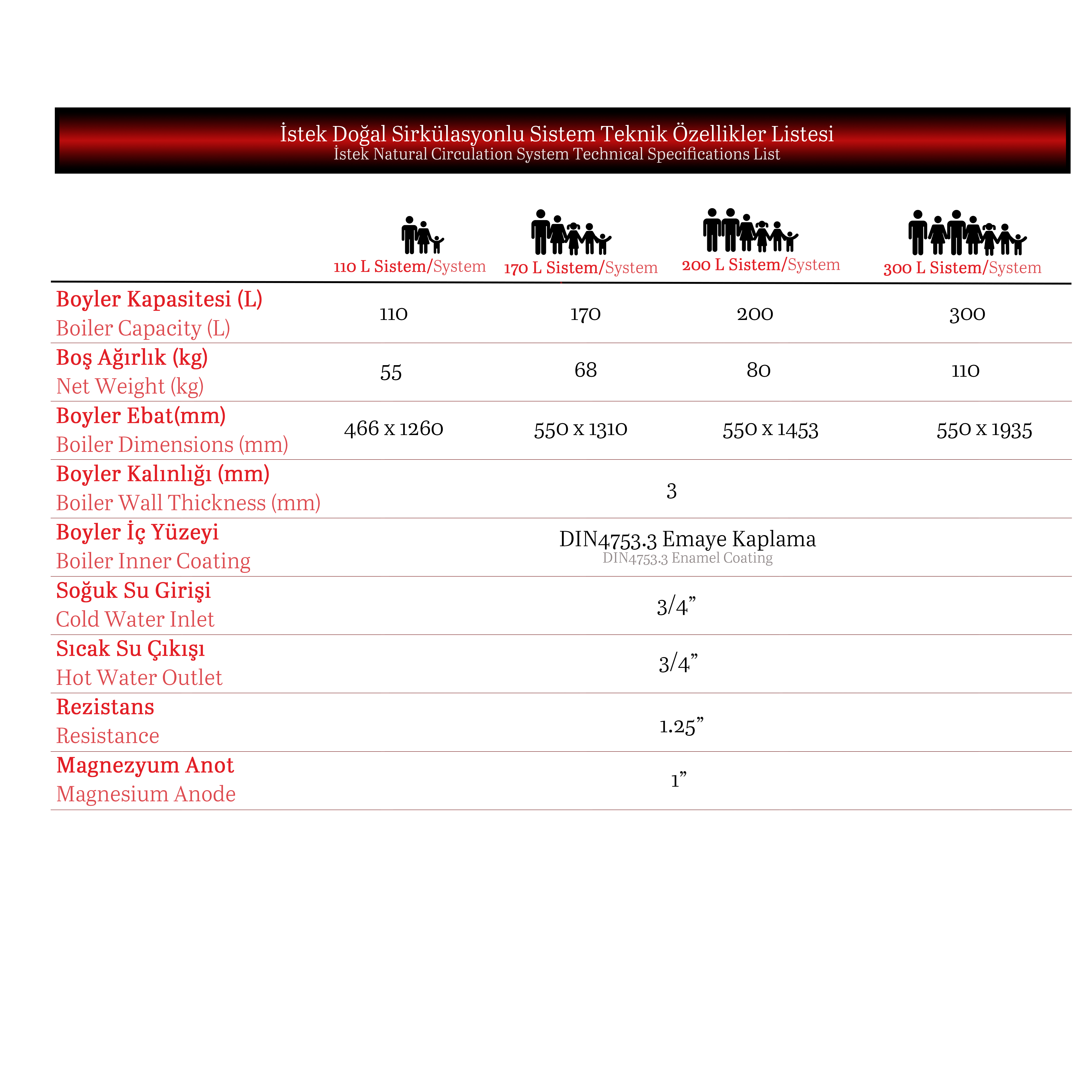

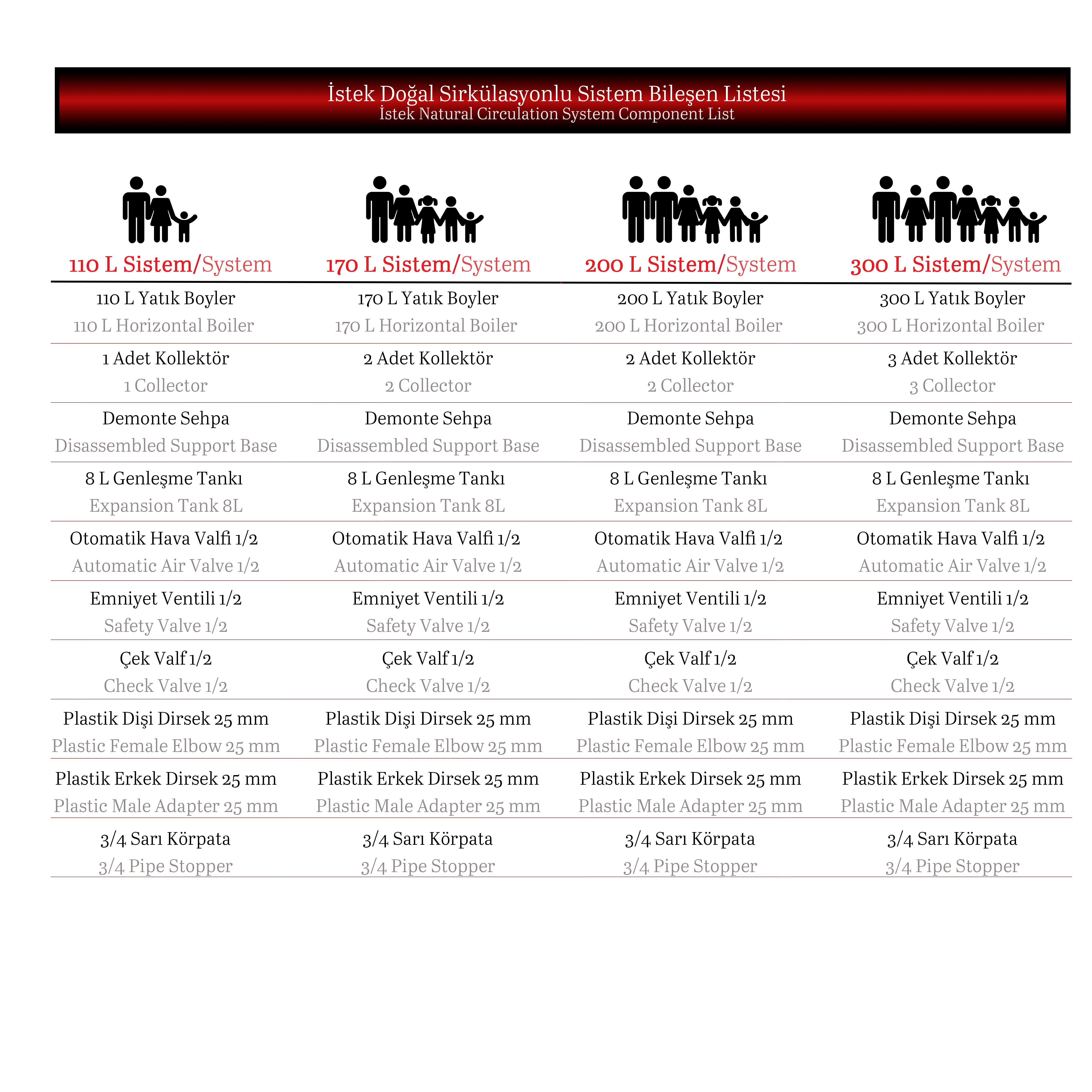

HORIZONTAL PRESSURIZED BOILER

Horizontal pressure boilers offer flexible installation options with their horizontal design and provide an indispensable solution for natural circulation systems. In these boilers, the heat transfer liquid circulates within a special jacket structure without mixing with the domestic water, ensuring efficient energy transfer. These boilers are compatible with solar collectors and utilize natural circulation to move water, offering a safe and efficient hot water solution. With high pressure resistance, durable material construction, and a long-lasting design, horizontal pressure boilers are an excellent choice for both individual and commercial use, delivering eco-friendly performance and energy-saving features.

SOLAR ENERGY SYSTEMS

Natural Circulation Systems

Closed-loop natural circulation systems minimize energy consumption and reduce operating costs as they do not require the use of pumps. Thus, the system operates efficiently with lower energy while also reducing maintenance requirements. The closed-loop structure eliminates the risk of freezing, ensuring safe use, especially in cold climates. It is ideal for small and short-distance installations, offering an efficient and economical solution due to its simple design.

Pumped Systems

In closed circuit pumped systems, liquid movement is controlled by the pump, providing fast and efficient flow. This system can work effectively in large areas by increasing the distance between the collector and the vertical boiler. In addition, since the vertical boiler does not have to be right above the collector, the boiler can be positioned at any point you want. Energy efficiency is increased by using the pump, and the system can be optimized according to different application needs by providing flexibility in design. Thanks to the closed circuit structure, the risk of freezing is eliminated and it provides safe use in cold climates. These systems offer high efficiency, reliability and flexibility for large areas.

Can Solar Energy Systems Be Used in Cold Climates?

Solar collectors can also be used in cold climates. Solar collectors absorb sunlight with their selective surfaces and convert it into heat, so they can operate effectively not only in warm climates but also in cold climates. In cold regions, the efficiency of collectors depends on the intensity and continuity of sunlight. In such systems, antifreeze fluids and closed-loop systems are often used to prevent freezing risks. In solar collectors used in cold climates, additional precautions need to be taken against adverse weather conditions such as freezing, snow, and icing. Closed-loop pumped or natural circulation systems with anti-freeze designs can work efficiently even in cold weather conditions.

How Can I Prevent Freezing Problems?

In regions prone to freezing, it is necessary to use closed-loop systems with antifreeze in solar collector systems. These systems are one of the most effective methods to prevent freezing in solar collectors. Instead of water, antifreeze (usually a propylene glycol mixture) circulates in the collector circuit. Antifreeze lowers the freezing point of the liquid, preventing it from freezing in cold weather conditions. This closed-loop system ensures that the antifreeze circulates within the collectors and transfers heat to the usage water through a heat exchanger. In this way, the system operates safely and uninterruptedly even in low temperatures.

How Can I Prevent Scaling and Sediment Build-Up?

Scaling and sediment build-up in solar collectors can negatively affect the efficiency of the system, but they can be prevented with proper measures. In open systems, water softeners or demineralized water should be used to reduce scaling caused by hard water. In closed-loop systems, this problem is largely prevented since antifreeze mixtures are used. During regular maintenance performed annually, system fluids can be checked and replaced, and deposits can be cleaned with descaling chemicals, preserving the system's efficiency and lifespan.

How Can I Minimize Dependency on Weather Conditions?

Various methods can be applied to reduce the dependence of solar collector systems on weather conditions, and the most effective is to use a hybrid energy system. Double-coil upright boilers allow seamless hot water supply by integrating solar energy and backup heating sources. The lower coil uses energy from solar collectors to heat the water, while the upper coil activates the backup energy source (e.g., a gas boiler or electric heater) when solar energy is insufficient. Thanks to intelligent control systems, solar energy is prioritized, ensuring energy savings while maintaining a continuous hot water supply. This setup provides energy efficiency and flexibility, creating a reliable solution for all seasons.

Is the Initial Installation Cost High?

While solar collector systems may have a slightly higher installation cost compared to electric heaters and gas boilers, they offer significant advantages with energy savings and low operational costs. Although the installation cost of electric heaters is low, their operational costs are high. For gas boilers, operational costs vary depending on energy prices, and the cost of installing the gas infrastructure must also be considered, making their overall installation cost much higher. Solar collector systems minimize operational costs by using solar energy as their source. The direct conversion of solar energy into heat energy, the absence of fossil fuel use, and minimal energy conversion losses make these systems an eco-friendly and efficient solution. These systems pay for themselves within 5-6 years and can be used efficiently for 20-25 years with regular maintenance. In the long run, solar collector systems provide significant advantages in terms of sustainability, energy efficiency, and savings.

How Can I Prevent Efficiency Loss in Solar Energy Systems?

To maintain efficiency in closed-loop and open-loop solar energy systems, regular maintenance and cleaning must be performed. In closed-loop systems, fluid levels and antifreeze ratios should be checked to ensure the correct dosage of antifreeze. Additionally, properly insulating pipelines prevents heat loss. In open-loop systems, water quality should be regularly monitored, and water softeners can be used to address scaling and sediment build-up. In both systems, maintaining high fluid quality prevents corrosion and sediment build-up, while using efficient pumps reduces energy consumption. The system pressure should be regularly monitored, and fluid levels should not decrease. In open-loop systems, temperature levels should be controlled to prevent overheating, and in regions at risk of freezing, antifreeze should be added or the system should be temporarily deactivated. These measures ensure that both systems operate at high efficiency for extended periods.